Kategorie

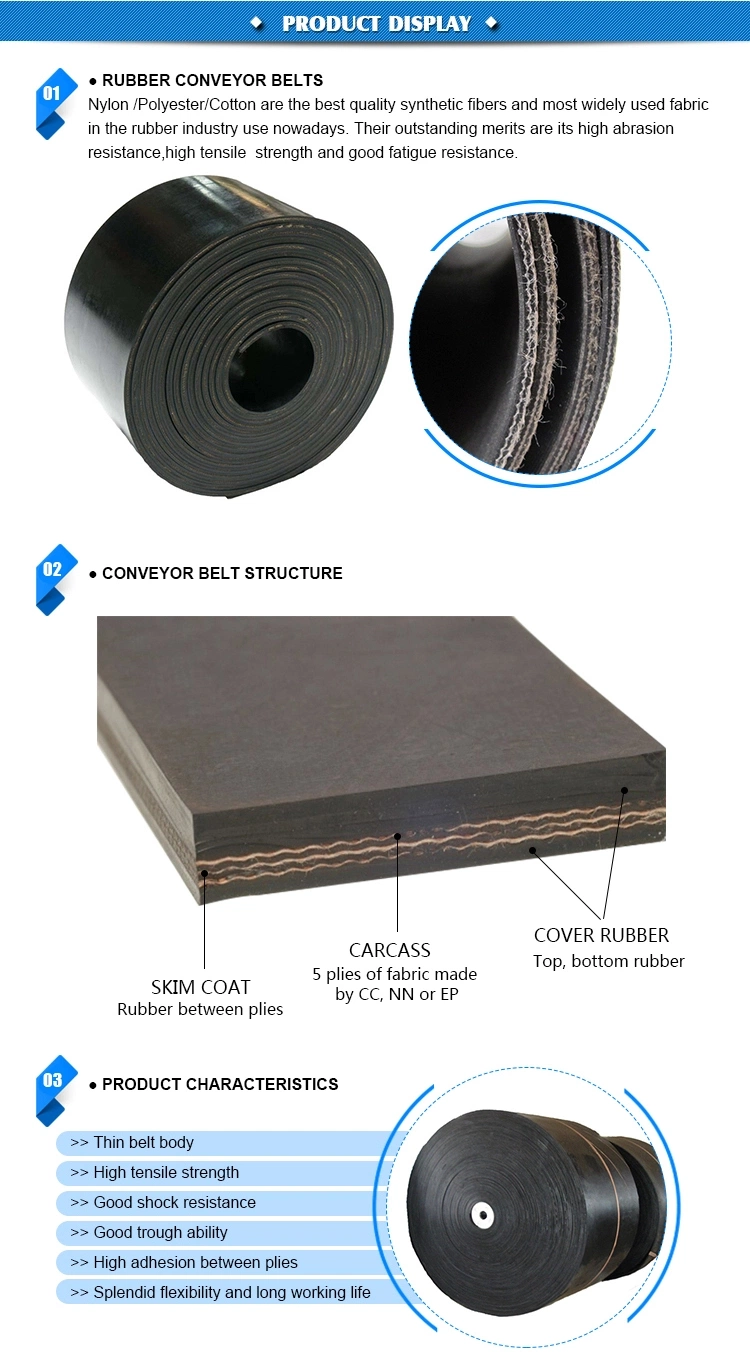

Maßgeschneidertes OEM-Förderband aus industriellem PVC-Canvas/Stahlschnur/Ep/Nylon/Chevron/gewellte Seitenwand/Gewebe/Polyester/Chevron-Gummi-Förderband/kontinentales Förderband

Gummileistungsniveaus von Förderbändern Wir sind der autorisierte Vertreter von Continental Belt in China und können Ih

Basisinformation.

| Modell Nr. | CEMA DIN AFNOR hatte gerade einen Bachelor |

| Standards | Hg/T 4062–2008, DIN22102, Sans1173, JIS K6322 |

| Deckungsdicke Uppertlower | 0-4,5 |

| Bezugsstärke oben | 1,5-12 |

| Zustand | Neu |

| OEM oder nicht | OEM erlaubt |

| Kostenlose Probe | Verfügbar |

| Lieferzeit | Entsprechend der Menge Ihrer Bestellung |

| Anwendungen | Kohle, Bergbau, Zementwerk, Kraftwerk |

| Gummiqualität der Abdeckung | Rma1, Rma2, DIN-W, DIN-X, DIN-Y, DIN-K |

| Zugfestigkeit von Gummi | 10 MPa, 12 MPa, 15 MPa, 18 MPa, 20 MPa, 24 MPa |

| Exportmärkte | Global |

| Gürtelstärke | 630n/mm |

| Riementyp | Offener Typ |

| Rand | Geformter Rand |

| Transportpaket | Verpackung von Holzkisten und Paletten |

| Spezifikation | BW650, BW800, BW1000, BW1200, BW1400, BW1600, |

| Warenzeichen | KONWEYOUR |

| Herkunft | Hengshui, China |

| HS-Code | 4010120000 |

| Produktionskapazität | 5000 M/Tag |

Produktbeschreibung

Gürteltyp | Gewebe-Art | Einzelgewebestärke (N/mm) | Dicke der Gummiabdeckung (mm) | Gesamt Dicke (mm) | Lagen | Riemenbreite (mm) | Riemenlänge (m)/Rolle | |

Obergummi | Bodengummi | |||||||

Baumwoll-Canvas (CC) Förderband | CC-56 | 56 | 3,0-6,0 | 1,5-6,0 | 3-30 | 3-12 | 300-2800 | 200 |

Nylon (NN) Förderband | NN100 | 100 | ||||||

NN150 | 150 | |||||||

NN200 | 200 | |||||||

NN250 | 250 | |||||||

NN300 | 300 | |||||||

NN400 | 400 | |||||||

NN500 | 500 | |||||||

NN600 | 600 | |||||||

Polyester (EP) Förderband | EP100 | 100 | ||||||

EP150 | 150 | |||||||

EP200 | 200 | |||||||

EP250 | 250 | |||||||

EP300 | 300 | |||||||

EP350 | 350 | |||||||

EP400 | 400 | |||||||

EP500 | 500 | |||||||

EP600 | 600 | |||||||

Gummileistungsniveaus von Förderbändern

Levelcode | Zugfestigkeit Mpa≥ | Bruchdehnung % ≥ | Verschleiß mm3 ≤ |

D | 18 | 400 | 90 |

H | 25 | 450 | 120 |

L | 20 | 400 | 150 |

P | 14 | 350 | 200 |

Hinweis: D – Arbeitsbedingungen mit starkem Verschleiß; H – Arbeitsbedingungen mit starkem Zugriss; L – allgemeine Arbeitsbedingungen; | |||

We are the authorized agent of Continental Belt in China and we could provide competitive price for you. The conveyor belt is a composite product of rubber, fiber, metal, or plastic and fabric used for carrying and transporting materials in the belt conveyor belt. Conveyor belts are widely used in cement, coking, metallurgy, chemical industry, steel and other industries.Conveyor belt and belt conveyor are widely used in agriculture, industrial and mining enterprises and transportation industry to transport various solid block and powder materials or finished articles. The conveyor belt can be used continuously, efficiently, and at a large angle. The conveyor belt is safe to operate. The conveyor belt is simple to use, easy to maintain, and low in freight. It can also shorten the transportation distance, reduce the project cost, and save manpower and material resources.Strength standard of conveyor beltCommon conveyor belt shall comply with GB7984-2001 standard.Ordinary conveyor belt: covering layer: tensile strength is not less than 15Mpa, breaking elongation is not less than 350%, and abrasion is not less than 200mm3; The average value of longitudinal sample of interlaminar bonding strength between layers shall not be less than 3.2N/mm; The distance between the covering glue and the cloth layer shall not be less than 2.1N/mm; The longitudinal tensile elongation of full thickness shall not be less than 10%; The elongation of the longitudinal reference force of the full thickness shall not be greater than 1.5%.The covering layer of nylon (NN) and polyester (EP) conveyor belts shall have a tensile strength of not less than 15Mpa and a elongation at break of not less than 350%. The average value of the longitudinal sample of the interlaminar adhesive strength shall be not less than 4.5N/mm between layers, not less than 3.2N/mm between the covering glue and the cloth, not less than 10% of the longitudinal tensile elongation of the full thickness, not more than 4% of the longitudinal reference force elongation of the full thickness. The covering glue shall be made of rubber and plastic, and the tensile strength coefficient of the skeleton at the national standard level, It can be lapped into a ring.